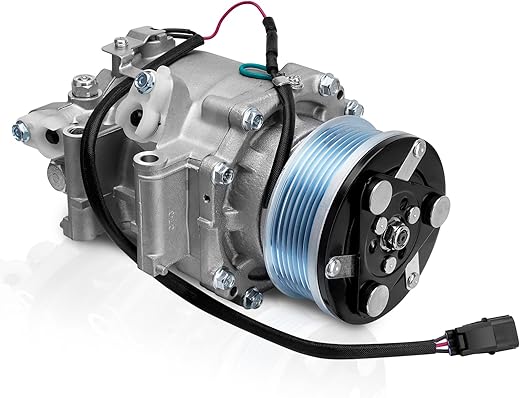

This step-by-step guide offers a comprehensive approach to safely removing and installing a new air conditioner compressor. It breaks down the process into manageable steps, ensuring that even those with minimal experience can follow along. Key instructions include safely disconnecting power, removing refrigerant, detaching the old compressor, and carefully installing the new unit. With clear guidance, this guide aims to help you complete the task efficiently, ensuring your air conditioning system operates optimally.

Gather all necessary tools before starting the replacement process. Ensure you have the following items ready:

- Socket set: Use this for removing bolts and nuts securely.

- Wrenches: Keep both adjustable and fixed wrenches on hand for various sizes of fittings.

- Screwdrivers: Have both flathead and Phillips screwdrivers available for any screws you may encounter.

- Safety equipment: Wear gloves and goggles to protect yourself while working. This helps prevent injuries from sharp edges or debris.

Procure a compatible replacement compressor along with any additional materials needed for installation. Check your vehicle’s specifications to ensure compatibility. Gather the following:

- Seals: Ensure you have the correct seals to prevent leaks during installation.

- Refrigerant: Purchase the right type and amount for your system, as this is crucial for proper functioning.

- Replacement parts: Double-check that you have all necessary components to make the installation seamless.

By preparing everything in advance, you set yourself up for a smoother and more efficient replacement process.

Disconnect Power and Prepare the Workspace

Disconnect the power to the air conditioning unit by locating the circuit breaker panel. Switch off the breaker that supplies power to the air conditioning system. If your unit has a disconnect switch, ensure that it is turned off as well. Verify that the power is indeed off by checking the unit for any signs of operation or by using a voltage tester. This crucial step prevents any accidents, ensuring a safe environment while you work on the compressor.

Clear the workspace around the compressor by removing any obstacles, tools, or debris that may hinder your movement. Create a clean area that allows for easy access to the unit from all sides. Ensure that there is enough room to maneuver and position tools without restriction. Organize your tools in a way that keeps them within reach, minimizing any unnecessary movements while you work. A tidy workspace not only enhances safety but also improves efficiency as you tackle the tasks at hand.

Remove the Old Compressor

Carefully disconnect the refrigerant lines from the old compressor by using a wrench or appropriate tool. Ensure you have a pan or container ready to catch any refrigerant that may escape during this process. Slowly loosen the fittings on the refrigerant lines, taking care not to damage any surrounding components. Once the lines are free, proceed to disconnect the electrical connections by removing the wire nuts or unscrewing any terminal screws. Make note of where each wire connects, as this will be vital when you install the new compressor. Taking pictures can be very helpful for reference later.

Use a socket wrench or a ratchet to unscrew and remove any mounting bolts that secure the old compressor in place. Make sure you have the right size socket to avoid stripping the bolts. After all bolts are removed, lift the old compressor out of the unit with caution, as it may be heavier than expected. Set the old compressor aside in a designated area for proper disposal or recycling. Ensure the workspace is clear and organized so you can easily access the new compressor when you’re ready for installation.

Install the New Compressor

Position the new compressor in place by carefully lining it up with the existing mounting brackets. Ensure that the compressor sits flat against the mounting surface, as any misalignment can cause operational issues later on. Once aligned, insert the mounting bolts through the compressor’s mounting holes and tighten them securely using a socket wrench. Check that the compressor is firmly held in place by giving it a gentle shake; it should not budge. For example, if you notice that one side is higher than the other, loosen the bolts slightly, adjust the position, and retighten them once it’s level.

Reconnect the refrigerant lines and electrical connections by first consulting the manufacturer’s instructions for guidance on proper routing and attachment. Begin with the refrigerant lines, ensuring they are free from debris and that the seals are intact. Thread the lines back onto the compressor, tightening them with a wrench until snug, but be careful not to overtighten, as this can damage the fittings. Next, connect the electrical wires, matching them according to color and function to prevent any wiring mistakes. Secure all connections with the appropriate fasteners, and double-check that everything is tight and correctly positioned before moving on. For instance, if you have a green wire for grounding, ensure it connects to the compressor’s designated ground terminal.

Test the System

Reconnect the power supply by plugging it back in or turning on the circuit breaker. Switch on your air conditioning unit and set the thermostat to a low temperature to prompt the system to cool. Carefully listen for any unusual noises such as rattling, hissing, or grinding that might indicate an issue with the installation. Pay attention to the compressor’s operation and ensure it runs smoothly without irregular sounds. Inspect the area around the newly installed compressor for any signs of leaks. If you observe any refrigerant dripping or pooling, immediately turn off the unit and address the issue before proceeding.

Monitor the air conditioning unit’s cooling performance. Place your hand near the air vent to check if the air coming out is cool and consistent. Wait for a few minutes to allow the system to reach its optimal performance. If the air feels warm or the unit cycles on and off excessively, turn it off and reassess your installation for any missed steps or connections. Once you confirm that everything runs smoothly and the cooling is effective, pat yourself on the back—your installation is complete!

Final Thoughts and Tips

In conclusion, replacing your air conditioner compressor doesn’t have to be daunting. With proper preparation, the right tools, and the steps outlined in this guide, you can confidently tackle the installation process. Not only will you restore cool comfort to your home, but you’ll also gain a sense of accomplishment. Remember to prioritize safety and take your time—your efforts will pay off with a perfectly functioning air conditioning system. Happy cooling!

Essential Equipment List

Essential Insights

Step-by-Step Guide to Safely Replace Your Air Conditioner Compressor

- Gather Your Tools and Materials: Before you start, make sure you have the necessary tools, such as a socket set, wrenches, screwdrivers, and a refrigerant recovery machine. You’ll also need a new compressor and any additional parts like O-rings or refrigerant

- Turn Off Power and Disconnect: Safety first! Turn off the power to your air conditioning unit at the circuit breaker. Disconnect the power supply to avoid any electrical mishaps while you’re working

- Drain the Refrigerant: Use a refrigerant recovery machine to safely remove the refrigerant from your system. This step is crucial as it prevents harm to the environment and complies with regulations

- Remove the Old Compressor: Disconnect the necessary lines and electrical connections from the old compressor. Carefully unbolt it from its mount and take it out. Remember to keep track of how everything is connected for reassembly!

- Install the New Compressor: Place the new compressor into position, secure it with bolts, and reconnect the electrical and refrigerant lines. Make sure to use new O-rings to prevent leaks. Finally, recharge your system with refrigerant following the manufacturer’s guidelines

- By following these steps, you’ll be on your way to successfully replacing your air conditioner compressor! If you feel unsure at any point, don’t hesitate to consult a professional

I think it’d be interesting to see a video tutorial along with the guide! Sometimes seeing the process really helps, especially for visual learners.

I replaced my Goodman compressor last summer and learned the hard way to double-check the refrigerant levels after installation. It’s super crucial! Just a heads-up for anyone doing this.

Great guide! I just replaced my old Trane compressor, and it worked like a charm using your steps. I think it would be awesome if you could do a follow-up on how to clean and maintain compressors for better longevity. Thanks!

Has anyone here tried DIY compressor replacement on an older model like a Lennox? I’m curious about any additional challenges or tips you might have!

Hi! Older models can definitely have some quirks. One challenge is often dealing with rusted bolts. A good tip is to use penetrating oil beforehand. Makes it a lot easier! Good luck!

Once I get everything set up, how long should I wait to test the system? I just want to make sure I’m doing it right. Thanks!

Great question! After installation, it’s usually best to let the system sit for about 30 minutes before testing. This allows the refrigerant to settle and ensures everything is in place. Happy testing!

Can you explain a bit more about how to properly evacuate the system before installing the new compressor? I think I might have missed that part.

This guide was super helpful, but I had to modify it a bit since my compressor was mounted differently. I ended up using a ratchet strap to hold it in place while I connected the lines. Just a little hack I thought I’d share!

Thanks for sharing your hack! It’s always great to hear about adaptations that make the job easier. Every installation can be unique, and your tip might just help someone else out!

I’ve done a few compressor swaps before, and I usually use a vacuum pump after installation to remove moisture from the system. Just a tip for anyone looking to ensure efficiency!

Does anyone have tips on what to do if the new compressor doesn’t turn on after installation? I followed the steps, but I’m not sure if I missed something. Any advice?

Hey! If your new compressor isn’t turning on, double-check all your electrical connections and make sure the power is properly restored. Sometimes, it’s just a blown fuse or tripped breaker. Good luck!

What are the best brands for replacement compressors? I’m looking to replace mine, but I want to make sure I get something reliable. Any recommendations?

Hey there! For reliable replacement compressors, I recommend looking into brands like Copeland, Carrier, or LG. They all have solid reputations in the industry. Hope this helps!